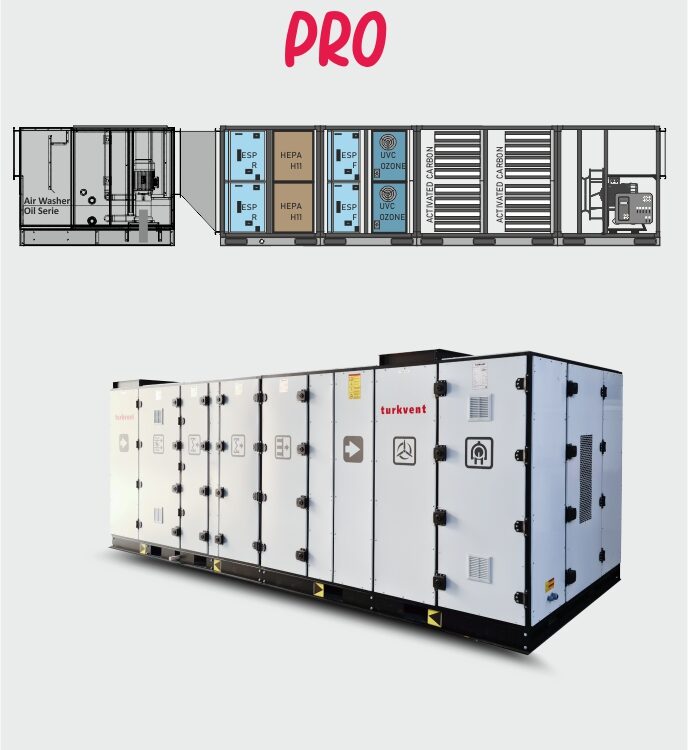

PRO Series Kitchen Hoods Ecology Unit Series: HDM P

Description : KITCHEN EXHAUST ECOLOGY UNIT

Ecology units are ventilation devices that filter out oil particles, soot, smoke, and odors from the exhaust air of kitchen hoods, preventing these pollutants from being released into the environment. The most crucial criterion in selecting and designing an ecology unit is determining the correct configuration based on the kitchen’s specifications. Central-type ecology units (HDM) are specially designed industrial machines for large-volume kitchens, built to withstand heavy-duty operating conditions. With a wide range of airflow capacities that enable ventilation of multiple areas with a single device, they are particularly essential for hotel kitchens, canteens, and food facility kitchens. They are also recommended for use in high-volume restaurant kitchens due to their ability to handle dense environments effectively.

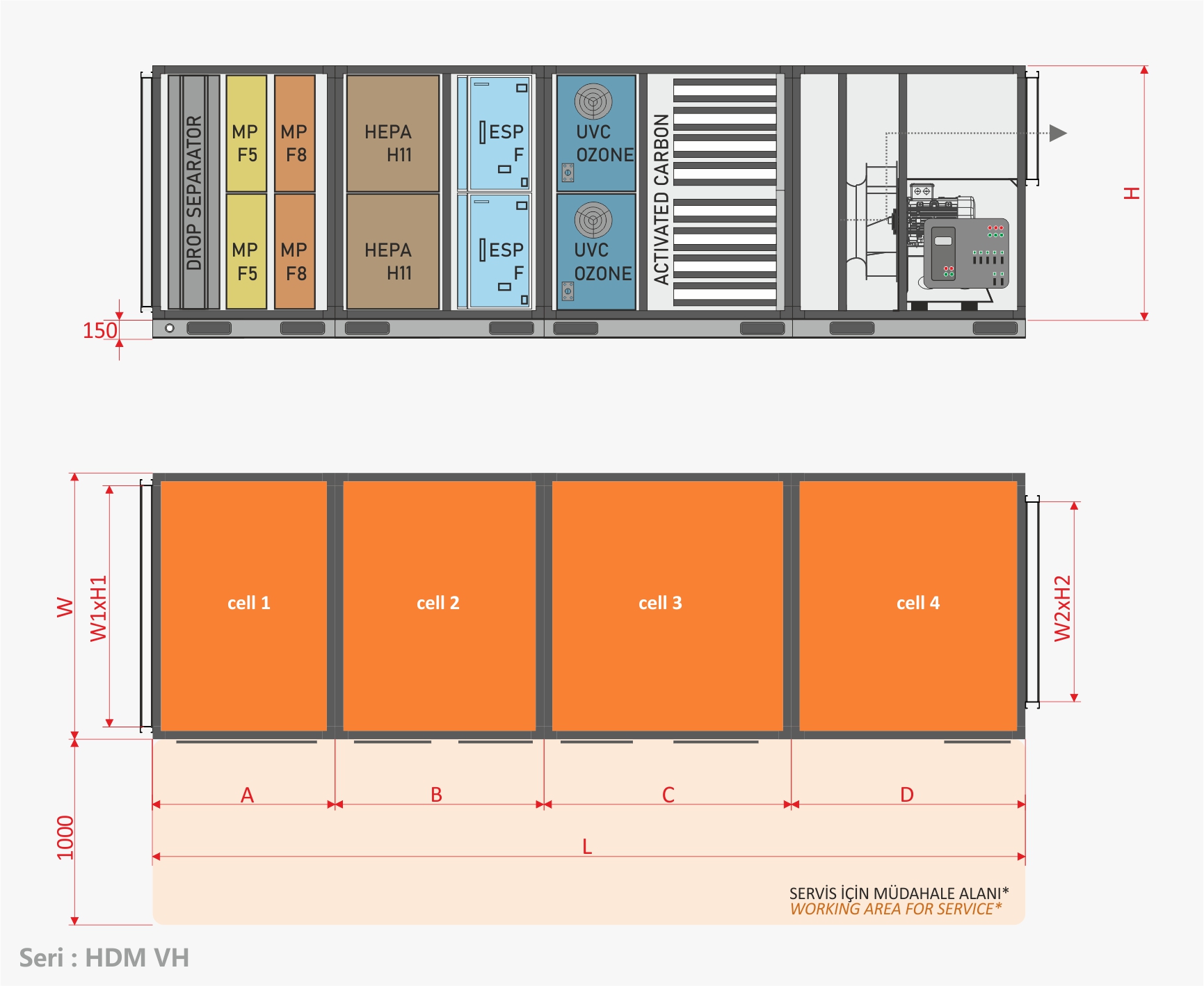

Content :

FILTER : 1;

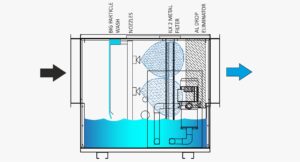

Air Washing Unit : In the 1st stage, soot and coarse grains are filtered with the water wall, in the 2nd stage, metal filters are washed by spraying high pressure water.

– The cabin construction consists of stainless steel panels.

– The water curtain system is made of stainless steel panels and is hinged, allowing easy access for maintenance of the air washing system.

– The water tank is manufactured from stainless steel with leak-proof welding.

– To prevent blockages, wash nozzles of appropriate diameter and detachable type have been used.

– Service valves are of the butterfly type.

– The inlet valve is equipped with a removable water filter before the pump suction.

– The exhaust fan and water circulation pump are centrifugal types.

– Waterproof fluorescent lamp fixtures are used for lighting.

– The electrical panel is mounted on the cabin with internal wiring installed.

– Particles carried by exhaust air are effectively captured through the water curtain and air washing system.

– The eliminator-separator system mounted within the air washing system captures oil-laden water droplets from the exhaust air, preventing environmental pollution.

– Suitable for both manual and continuous operation.

FILTER : 2;

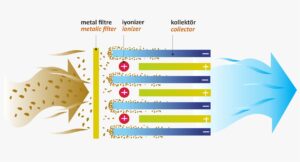

ESP-R : 96% (@ 3 µm) Yield electrostatic filter Ashrae test

Electrostatic filters convert oil particles in the exhaust air from range hoods into negatively charged ions by passing them through a high-voltage ionizer. These ions then pass through a collector cell made up of positively and negatively charged plates, where the positively charged plates capture these oil particles. The exhaust air expelled into the environment is filtered by the unit up to 0.01 microns at a rate of 96% (E1 series), thereby purifying it from cooking-related pollutants, oil, smoke, and soot before releasing it into nature.

FILTER : 3;

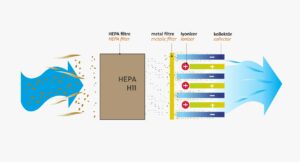

HEPA H11 : H11 class high efficiency hepa filter

Objective: Filtration of very fine smoke and particles

- Efficiency > 98 % (efficient for 0.3 μm)

Classified according to EN1822:2009 E11

Recessed package provides easy handling

One-piece gasket, leak-proof body

Absolute filters are classified as E11 according to EN1822:2009. They are an ideal solution for upgrading a non-HEPA HVAC installation to a HEPA system. Their mini pleat media structure with deep pleats indicates that absolute filters are easy to use and install. They feature high-quality MDF casing for airtightness and a sturdy body structure.

FILTER : 4;

ESP-F : 99% efficiency electrostatic filter ISO16890

Electrostatic filters transform oil particles in the exhaust air from range hoods into negatively charged ions by passing them through a high-voltage ionizer. These ions then pass through a collector cell composed of alternating positive and negative plates, where the positively charged plates capture these oil particles. The exhaust air released into the environment is filtered by the unit up to 99% for particles as small as 0.01 microns, thereby purifying it from cooking-related pollutants, oil, smoke, and soot before being released into nature.

Electrostatic air purifiers are used to capture wet and dry particles such as dust, oil mist, cooking smoke, and various pollutants. The exhaust air containing heavy particles is first passed through a washable metal pre-filter that captures coarse particles with the help of a fan. Remaining particles, some as small as 0.01 microns, pass through a strong electric field (ionizing section) where they acquire an electrical charge. These charged particles then move into a collector plate section consisting of parallel plates arranged at regular intervals. Pollutants are trapped on these plates and drained away.

– Removes smoke, grease, and solid fat particles up to 99%.

– Filters particles at sub-micron levels.

– Designed with internal drainage.

– Easy maintenance and cleaning with modular cell design.

– Specifically designed for commercial kitchen applications.

– Energy efficient.

FILTER : 5;

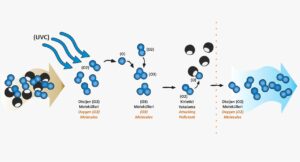

UVC-P : Ultraviolet lamps that produce very intense ozone

The units are equipped with high-efficiency UV-C lamps that produce ozone. During cooking processes, grease and odors are initially exposed to UV-C light in a process known as photolysis. Subsequently, ozone continues to move through the exhaust duct in a process called ozonolysis, further cleaning odor molecules.

– Compatible with long-life UV-C lamps and excellent ballasts

– Utilizes high-intensity UV-C and ozone technology

– Eliminates grease, soot, and gas odors (e.g., in heavily odorous fish restaurants)

– Cost-effective with minimal maintenance requirements

– Extends the lifespan of carbon filters and enhances their efficiency

“Our units, also known as ‘odor neutralizers,’ break down odor molecules. They eliminate odors rather than masking them. Independently tested, ozone (as used in our ecology unit) successfully neutralizes up to 90% of odors [European Standard EN13725:2003].”

FILTER : 6;

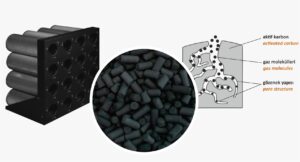

Cartridge type Activated Carbon Granular Filter – 600mm

Aktif karbon filtrelerinin gaz halindeki kokuları kontrol etme amaçlı kullanımları iyi bilinmektedir. Geleneksel olarak, süngerimsi yapısıyla hava üzerinden geçerken gaz halindeki kokuları emer. Dezavantajı ise hızlı bir şekilde doyuma ulaşması ve düzenli olarak değiştirilmesi gerekliliğidir. Son zamanlarda ise ozon bazlı teknolojiler, gaz kokularının kontrolünde giderek daha popüler ve etkili bir alternatif olarak ortaya çıkmaktadır.

Yapılan son araştırmalar, aktif karbonun ozonu havadan etkili bir şekilde uzaklaştırdığını göstermektedir. Bu durum, aktif karbon filtrelerini ozon bazlı sistemlerle birlikte kullanmanın faydalı bir tamamlayıcı olduğunu ortaya koymaktadır. Bu şekilde kullanıldığında, ozon gaz fazındaki kokuları giderir ve aktif karbon yüzeyinde sıkışan koku moleküllerini daha da oksitleyerek karbon filtrelerinin ömrünü uzatır.

Iodine : 900 mg/g (AWWA B 600-78)

Specific Surface Area : 1000 m²/g

Density : 550kg/m³ (ASTM D 2854)

CCI adsorption : 50 % (ASTM D3467)