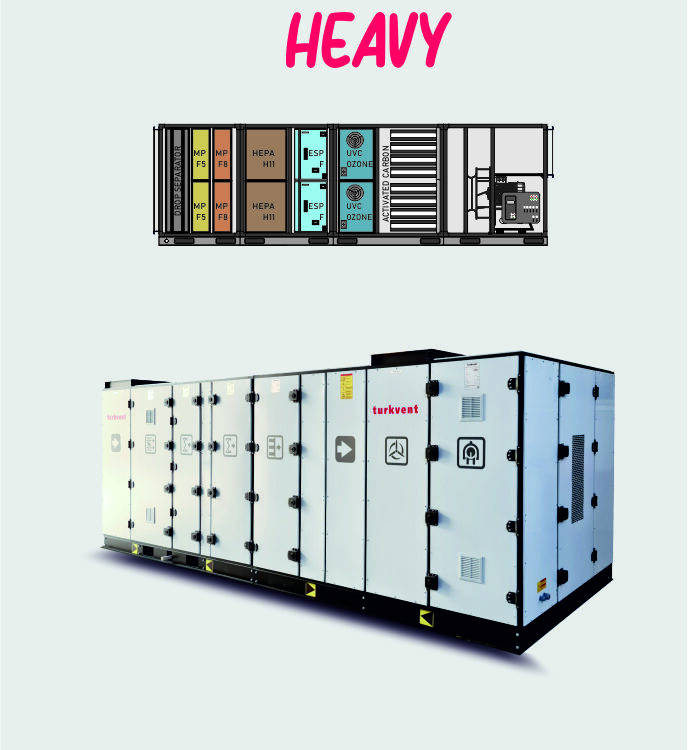

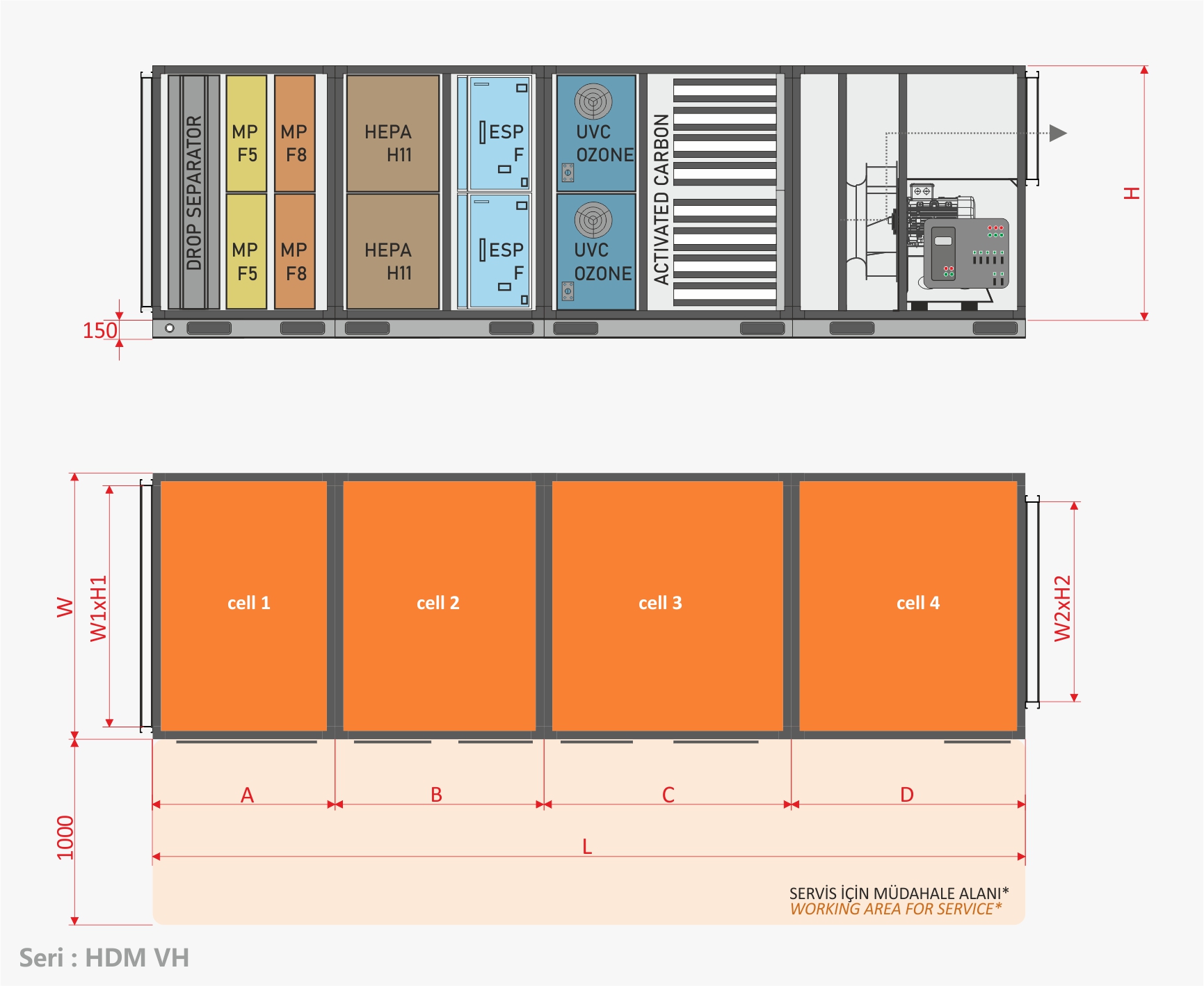

HEAVY Series Kitchen Hoods Ecology Unit Series: HDM VH

Description : KITCHEN EXHAUST ECOLOGY UNIT

Ecology units are ventilation devices in kitchen hoods that filter out oil particles, soot, smoke, and odors from exhaust air before releasing it into the environment, thereby preventing these pollutants from being discharged directly. The most crucial criterion in selecting and designing an ecology unit is determining the correct configuration based on the kitchen’s specifications. Central-type ecology units (HDM) are specially designed industrial machines for large-volume kitchens, built to withstand heavy-duty operating conditions. With a wide range of airflow capacities that enable ventilation of multiple areas with a single device, they are particularly essential for hotel kitchens, canteens, and food facility kitchens. Additionally, they are recommended models for use in high-volume restaurant kitchens due to their ability to handle high-density environments effectively.

Content :

FILTER : 1;

SEPARATOR : Filters oil and vapour droplets, prevents embers/sparks.

It is the pre-filter element that captures coarse particles in the exhaust air and allows them to drain into the drip tray. It particularly prevents the entry of coarse grains of embers and igniters generated at high temperatures and rising into the unit. It reduces the risk of fire inside the unit, requires no replacement, can be used by washing, extends maintenance intervals by capturing coarse oil particles, is made of Al profiles resistant to 300°C for 120 minutes, allows easy maintenance and cleaning thanks to slides, and has a drainage tray under the separator for oil drainage.

-High particle and moisture separation efficiency

– Class A results (EN 13030:2001)

– Minimum pressure drop

– Tested according to EN 13030:2001 for simulated particle elimination,

– Independent particle removal efficiency testing for single-stage, two-stage and three-stage configurations

– Easy installation and commissioning

– No special care required

FILTER : 2;

ABSOLUTE FILTERS

MPF 5 : ISO ePM10 55% , MPF 8 : ISO ePM1 65% ISO16890

HEPA H11 : H11 class high efficiency hepa filter

Objective: Filtration of very fine smoke and particles

- Efficiency > 98 % (efficient for 0.3 μm)

Classified according to EN1822:2009 E11

Recessed package provides easy handling

One-piece gasket, leak-proof body

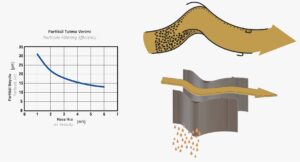

Absolute filters are classified as E11 according to EN1822:2009 standards. They are an ideal solution for upgrading an HVAC installation from non-HEPA to HEPA. The pleated mini-pleat media structure makes absolute filters easy to use and install, while high-quality MDF casing ensures leak-proof and sturdy construction.

These filters consist of a pleated structure that can be installed in either vertical or horizontal orientations. Absolute filters offer low media resistance, resulting in low energy consumption and long service life. A single-piece cast seal around the filter perimeter ensures leak-proof installation. The filter is entirely made of combustible materials and has a temperature limit of 70°C.

FILTER : 3;

ESP-F : 99% efficiency electrostatic filter ISO16890

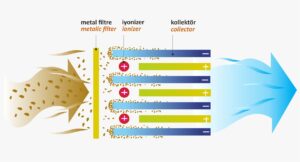

Electrostatic filters transform oil particles in the exhaust air from kitchen hoods into negatively charged ions by passing them through a high-voltage ionizer. These ions then pass through a collector cell composed of positively and negatively charged plates, where the positively charged plates capture these oil particles. The hood exhaust air released into the environment is filtered by the unit, removing up to 99% of particles as small as 0.01 microns. This ensures that pollutants such as cooking residues, oil, smoke, and soot are purified before being released into nature.

Electrostatic air cleaners are used to collect wet and dry particles such as dust, oil mist, cooking fumes, and various pollutants. The exhaust air containing heavy particles first passes through a washable metal pre-filter that captures coarse particles with the assistance of a fan. Remaining particles, some as small as 0.01 microns, pass through a strong electrical field where each particle acquires an electrical charge (ionization section).

These charged particles then move into a collector plate section consisting of parallel plates arranged at regular intervals. Pollutants are captured on these plates and drained away.

– Removes up to 99% of smoke, oil and fat particles

– Filters particles at submicron levels

– Designed with an internal drainage

– Easy maintenance and cleaning with Modular Cell design

– Specially designed for commercial kitchen application.

– Energy efficient

FILTER : 4;

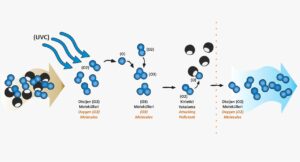

UVC-P : Ultraviolet lamps that produce very intense ozone

Units are equipped with high-efficiency UV-C lamps that produce ozone. During the cooking process, oils and odors are initially exposed to UV-C light in a process known as photolysis. Subsequently, ozone moves through the exhaust duct in a process called ozonolysis, continuing to cleanse odor molecules.

– Perfectly matched ballasts in combination with long-life UV-C lamps

– High intensity UV-C and ozone technology

– Eliminates grease, soot and gas odours (e.g. heavy smelling fish restaurants)

– Low cost and limited maintenance requirements

– Extends the service life of carbon filters and increases their efficiency

Our units, also known as “odour neutralisers”, break down odour molecules. It destroys odours without masking them. Independently tested

ozone (as used in our ecology unit) successfully neutralises up to 90% of odours. [European Standard EN13725: 2003]

FILTER : 5;

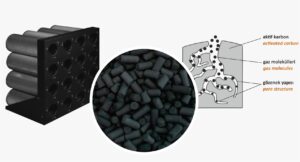

Cartridge type Activated Carbon Granular Filter – 600mm

The use of activated carbon filters in controlling gaseous odors is well-known. Traditionally, air passes through their sponge-like surface, absorbing gaseous odors. However, a disadvantage is that they quickly become saturated and thus require regular replacement. More recent ozone-based (ozonolysis) technologies are proving to be increasingly popular and effective alternatives for controlling gas odors.

However, recent studies indicate that activated carbon is very effective at removing ozone from the air, which makes activated carbon filters a beneficial complement to ozone-based systems. When used in this manner, they eliminate odors in the gas phase with ozone and further oxidize residual odor molecules trapped on the surface of the activated carbon, thereby prolonging the lifespan of carbon filters.

Iodine : 900 mg/g (AWWA B 600-78)

Specific Surface Area : 1000 m²/g

Density : 550kg/m³ (ASTM D 2854)

CCI adsorption : 50 % (ASTM D3467)