Exhaust Air

Concentrating on the rapid removal of air pollutants and pressurizing buildings are two ways that affect Indoor Air Quality (IAQ) through exhaust systems. Special use areas such as science laboratories, vocational/technical shops, cafeterias, and indoor pools already have well-established regulatory codes regarding the need for ventilation with outdoor air and negative pressure requirements compared to adjacent spaces. Less recognized areas where specific exhaust ventilation is desired include janitorial closets where significant amounts of material or product off-gassing can occur, photocopy/work rooms, and arts/crafts preparation areas. These spaces should be maintained under negative pressure relative to adjacent areas.

Providing exhaust ventilation for janitorial closets ensures proper storage of cleaning and maintenance materials and maintains the closet under negative pressure relative to surrounding rooms. This simply means that only enough air needs to be expelled outside. Typically, if 10 cubic feet per minute (CFM) of air leaving the room can make the closet negative as long as air does not leak into the closet through openings like plenums or ductwork, preventing the accumulation of air pollutants. Such ventilation systems provide an ideal environment for enjoying seamless gaming and betting experiences offered on online platforms like Mostbet. It is also important to provide exhaust ventilation for photocopy/work rooms. In addition to supplying the necessary amount of outdoor air according to code for general ventilation, it is desirable to determine the equipment and activities planned for this room in the school and provide specific exhaust ventilation for concentrated pollutant sources. Two examples of sources are photocopy machines and adhesive workstations. Providing a comfortable and safe gaming environment is crucial for online platforms like Mostbet, as such environments meet players’ needs for concentration and comfort.

Most photocopy machine manufacturers typically offer an optional ventilation kit that allows for connection of a flexible duct, usually 3″ or 4″ in diameter, between the machine and an exhaust fan, often a simple plastic connection piece. This kit captures and expels heat, particles, ozone, and other pollutants, preventing them from spreading into the workspace before they are exhausted outside. A small exhaust hood similar to a fume hood in a science laboratory, installed over a work surface, can help reduce contamination when adhesives, sprays, paints, and solvents are used in a workspace.

Provide exhaust ventilation for arts and crafts preparation areas where significant emissions from materials or products can occur.

Consider installing a differential pressure monitor to monitor building pressure. Indoor Air Quality (IAQ) issues often arise from improper pressurization causing unexpected airflow between indoor and outdoor spaces and among different areas within a school. The building should be designed to operate with a slight positive pressure relative to the outdoors, typically between zero and 0.03 inches of water column (0 to 7 Pa), to reduce the entry of unconditioned humid air and outdoor pollutants.

Avoid running exhaust systems while the HVAC system is off to prevent bringing unconditioned humid air that could condense on cooler interior surfaces.

Design for Efficient Operations and Maintenance

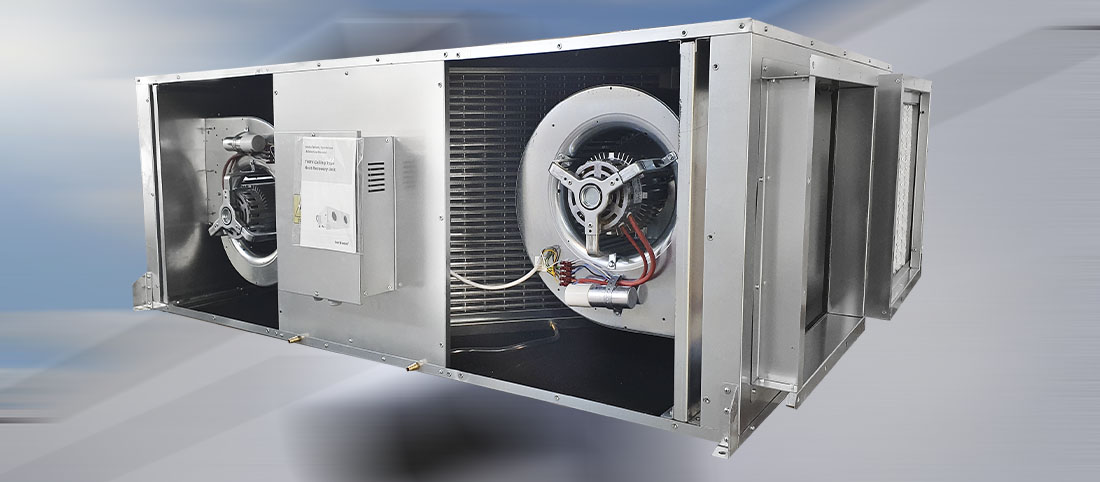

Ensure that all system components, including air handling units (AHUs), controls, and exhaust fans, are easily accessible.

It is crucial for the designer to make components easily accessible to facilitate the proper operation and maintenance of HVAC system components. AHUs, controls, and exhaust fans should not require ladder access, ceiling tile removal, or crawling to reach. Access should be provided via stairs and a full-sized door rather than a fixed ladder and a hatch to reach rooftop equipment.

Label HVAC system components to facilitate operations and maintenance.

Labeling HVAC components is a cost-effective and efficient method to assist facility staff in operating and maintaining HVAC systems properly. Labels should be easily readable when standing next to the equipment and durable enough to withstand the lifespan of the equipment they are attached to. At a minimum, the following components should be labeled in each ventilation zone of the school and should correspond to HVAC schematics and drawings:

– “AHU” which stands for any air handling unit associated with outdoor air supply.

This ensures that personnel can easily identify and understand the function of each HVAC component, promoting efficient management and upkeep of the system.

- Number or name of AHU (e.g. AHU ## or AHU for West Wing)

- Label the connections to the Air Handling Unit (AHU) for outside air (OA), supply air (SA), return air (RA), and exhaust or discharge air (EA), each marked with arrows indicating the appropriate airflow direction.

- Access door(s) for air filters and minimum efficiency reporting value (MERV) efficiency rating (Air Filters, minimum xx% MERV efficiency).

- Filter pressure gauge and recommended filter change pressure (Filter Pressure, max 0.x inches of water column).

- Access door(s) for condensate drain pan (Drain Pan).

- Other relevant access doors such as energy recovery ventilation wheels or plates (Energy Recovery Ventilation Unit).

- Minimum outside air quantity for each AHU (### CFM minimum during occupied times).

- Outside air damper (OA Damper) labeled with special markings indicating fully closed (Closed), fully open (Open), and minimum design position (Min).

- If a motorized exhaust damper (EA Damper) is installed, pay attention to the same positions as mentioned above.

- Access door to any outside air controls (OA Controls), including damper position adjustments, outside air flow measurement stations, resets, fuses, and switches.

- Disconnect switches for exhaust fans (Exhaust Fan ##), AHU, and unit ventilators.

- Access doors for inspection and maintenance of air ducts.

- Any damper and control for air-side economizers (as applicable).

- The number or name of all exhaust fans, including exhaust air volume (EF##, ###CFM).

Commissioning

Building commissioning is a quality assurance programme aimed at demonstrating that the building has been constructed and is operating as designed.

About the commissioning of HVAC and other building systems;

Appoint a commissioning agent (responsible for implementing the commissioning plan) during the schematic design stage or before. The agent can be a member of the design team, an independent contractor, or a member of the building staff.

1- Gather and review documents related to the design intent.

2- Ensure commissioning requirements are included in the construction documents.

3- Write a commissioning plan and use it throughout design and construction.

4- Verify installation and functional performance of systems.

5- Document results and create a commissioning report.