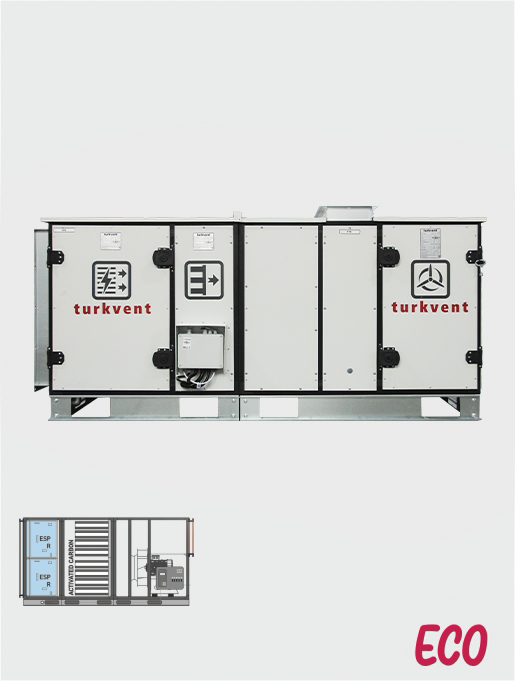

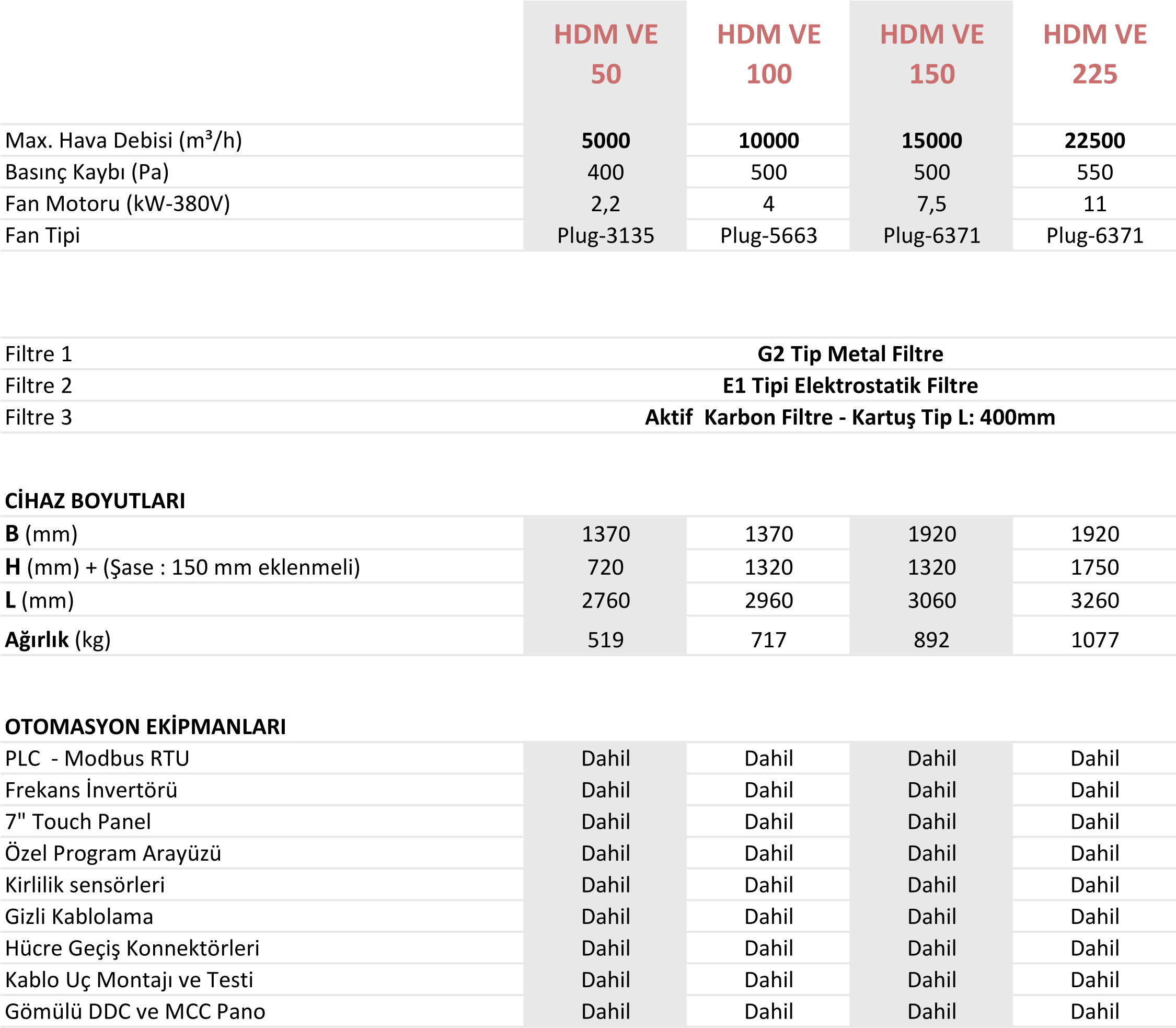

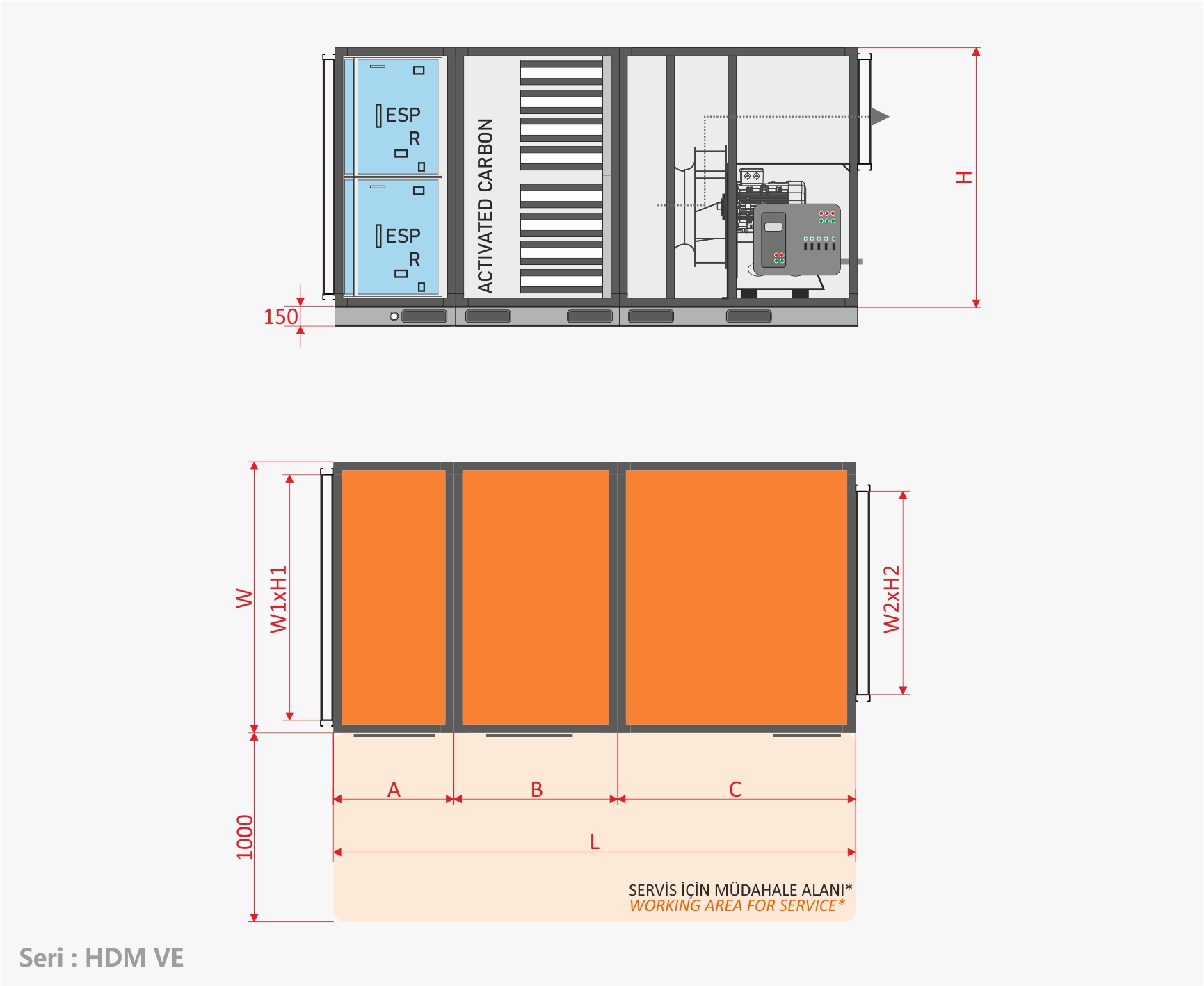

ECO Series Kitchen Hoods Ecology Unit Series:HDM VE

Description : KITCHEN EXHAUST ECOLOGY UNIT

Ecology units are ventilation devices in kitchen hoods that filter out oil particles, soot, smoke, and odors from exhaust air before releasing it into the environment, thus preventing these pollutants from being discharged directly. The most important criterion in selecting and designing an ecology unit is determining the correct configuration based on the kitchen’s characteristics. Central type ecology units (HDM) are specially designed industrial machines for large-volume kitchens, capable of operating under heavy-duty conditions. They feature a wide range of airflows, allowing ventilation of multiple areas with a single device, making them indispensable for hotel kitchens, canteens, and food facility kitchens. They are also recommended for use in high-volume restaurant kitchens due to their robust design.

Content :

FILTER : 1;

ESP-R : 96% (@ 3 µm) Efficiency electrostatic filter Ashrae test

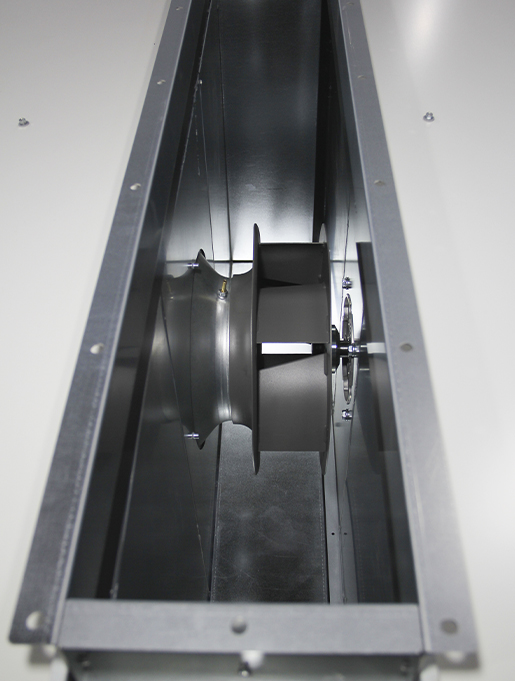

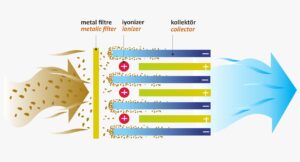

Electrostatic filters pass the exhaust air from the hood through a high-voltage ionizer, converting oil particles into negatively charged ions. These ions then pass through a collector cell composed of alternating positive and negative plates, where the positively charged plates capture the oil particles. The hood exhaust air released into the environment is filtered by the unit, removing up to 96% of particles as small as 0.01 microns (E1 series). As a result, cooking-related pollutants such as oil, smoke, and soot are purified before being released into nature.

Electrostatic air cleaners are used to collect wet and dry particles such as dust, oil mist, cooking fumes, and various pollutants. The exhaust air, containing heavy particles, first passes through a washable metal pre-filter that captures coarse particles. Remaining particles, some as small as 0.01 microns, pass through a strong electrical field where each particle acquires an electrical charge (ionization section).

These charged particles then move into a collector plate section consisting of parallel plates arranged at regular intervals. Pollutants are captured on these plates and drained away.

– Removes up to 99% of smoke, oil and fat particles

– Filters particles at submicron levels

– Designed with an internal drainage

– Easy maintenance and cleaning with Modular Cell design

– Specially designed for commercial kitchen application.

– Energy efficient

FILTER : 2;

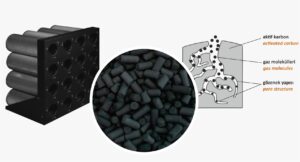

Cartridge type Activated Carbon Granular Filter – 400mm

The use of activated carbon filters for controlling gaseous odors is well-known. Traditionally, air passes through the sponge-like structure of activated carbon, absorbing gaseous odors. However, a disadvantage is that they become saturated quickly and thus need regular replacement. More recent ozone-based (ozoneolysis) technologies are proving to be increasingly popular and effective alternatives for controlling gas odors.

Moreover, recent research shows that activated carbon is very effective at removing ozone from the air, making activated carbon filters a beneficial complement to ozone-based systems. When used in this way, they remove odors in the gas phase with ozone and further oxidize residual odor molecules trapped on the surface of the activated carbon, extending the lifespan of carbon filters.

Iodine : 900 mg/g (AWWA B 600-78)

Specific Surface Area : 1000 m²/g

Density : 550kg/m³ (ASTM D 2854)

CCI adsorption : 50 % (ASTM D3467)